rockwell hardness tester tips|rockwell hardness tester chart : distributor The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. Termes et conditions. Le gain maximal est 25.000 TND

{plog:ftitle_list}

web23 de jan. de 2024 · Ver Resultado do Jogo do Bicho Loteria Nacional 1º ao 10º do dia 23/01/2024. Devido a falta de critério da Loteria Nacional na formação da multiplicação, a Resultado Fácil não estará mais exibindo (o 7º prêmio - Multiplicação, válido para resultado do 1º ao 5º), para que não haja confusão na conferência. Sugerimos para .

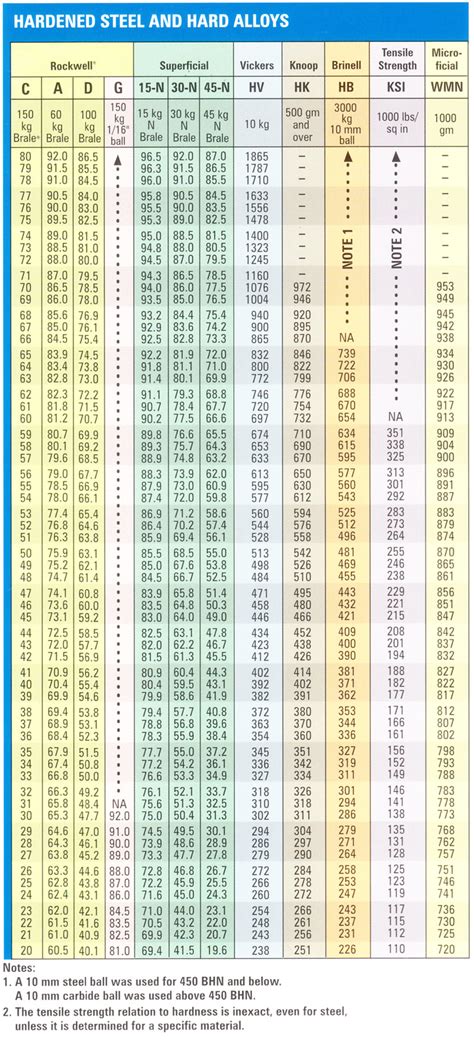

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.

Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators and the methods used are following proper test technique and practice. The precise nature and exactness of a Rockwell test .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on .Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a .Gilmore Diamond Tools’ manufactures diamond indenters and penetrators for all makes and models of Rockwell hardness testing machines – as well as custom indenters for use in difficult testing situations. We are the ONLY U.S. diamond indenter manufacturer accredited by the United States Department of Commerce / N.I.S.T. for the measurement and calibration of .

wilson rockwell hardness tester repair

rockwell hardness tester diagram

Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality .

Fig. 1: Typical Rockwell Hardness Tester What is Hardness? Hardness is the measure of the resistance of a material to an applied force, and involves the use of an indenter of fixed geometry under static load. Hardness can also refer to stiffness or temper, or to resistance to scratching, abrasion, or cutting.this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrial

rockwell hardness tester chart

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine. If using a portable Brinell hardness tester, exercise caution when removing the machine from the component so that the edge of the indentation is not accidentally damaged when the machine is released. 3. Rockwell Hardness Testing Preparation Figure 1. Close-up of Rockwell indentation. Cleanliness is everything in Rockwell testing.Rockwell and Microhardness Testing Top Tips. We’ve been building Rockwell hardness and microhardness testers for decades and we’ve learned a thing or two. You’ll find helpful testing insights throughout the knowledge base section of our website, where we publish articles exploring all manner of related subjects.The Rockwell hardness (HR) is then determined from the residual indentation depth, along with a few other factors (see below). In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as .

rockwell hardness test diagram

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs.Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .The 574 Series Wilson Rockwell Hardness Testers offer quality, durability, and an industry leading Gauge Repeatability and Reproducibility (GR&R) making this hardness testing machine best in class. This system is available in Regular or Twin Scale models and capable of testing in all of the regular and superficial Rockwell hardness scales and .The clamping ability is an inherent part of this Rockwell hardness tester and provides the user with the ability to clamp and hold parts in place prior to testing with up to 240 foot pounds (325 Nm). By clamping instead of using jack screws or cutting specimens, the test accuracy is improved and the testing time is decreased.

Rockwell Hardness Testers – Bench Analog Models Analog Rockwell Hardness Tester Phase II - Model 900-331 Rockwell Superficial Hardness Tester Phase II - Model 900-345 Rockwell/Superficial Twin Hardness Tester . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . To ensure accurate and reliable hardness values during testing, consider the following general tips: Sample preparation: Ensure that the sample surface is properly .

rockwell hardness test calculation

II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.

30 compressed gas spring

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. . Top Tips To Read A Dial Bore Gage. A dial bore gage is an instrument .

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

30 compressed length gas spring

DataView Software Version 1.6.0 Software Version 1.6.0 17-Jul-18. Added Features or Enhancements: 1) DataView now supports Rockey4ND license key in addition to the Rockey4, 2) Verification mode is improved for easier retrieval of previous verifications, 3) Added option to start DataView in Online mode, 4) Added option to include the original measurement in the data . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. . Tips and Tricks. Recommended Content. 1 Comment. S D Kulkarni says: January 9, 2021 at 1:19 am. Now a days the impact/rebound type . CIMETRIX offers the CMX1000 Portable Hardness Rockwell Tester Machine for measuring metal hardness in Rockwell C, Rockwell B, Vickers, Brinell and Shore scales. Welcome visitor you can login or create an account. Home Wish List (0) My Account Shopping Cart Checkout. Shopping Cart 0 item(s) - Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable hardness tester such as auto-probe detection, auto direction detector, single and multi-point calibration make the new 1900 the most versatile ..00.

ness is less significant than for Leeb D and C devices. The Portable Rockwell device determines the hardness according to the Rockwell principle while using a lower load of 50 N. • The scatter of hardness readings taken with impact devices D and especially C increases quickly with rougher surfaces.

Hardness Testers from Newage Testing Instruments - Quality Assured! Newage Testing Instruments is an established manufacturer and worldwide supplier of hardness testers and accessories, providing you with the ideal solutions for all your research and quality needs.

40 gas compression springs

8 inchlong heavy duty gas compression springs

AUD-20231112-WA0001 - download at 4shared. AUD-20231112-WA0001 is hosted at free file sharing service 4shared. Online file sharing and storage - 15 GB free web space. .

rockwell hardness tester tips|rockwell hardness tester chart